Comparative analysis of pricing parameters

Canadian Property Valuation Magazine

Search the Library Online

This article is a PhD dissertation by Roman Sustek, an appraiser who is currently studying at the INSTITUTE OF FORENSIC ENGINEERING in the Czech Republic. His paper deals with the issue of forming machine valuation utilizing an innovative approach known as the ECM method and computational modelling. In the dissertation, this procedure is applied to other forming machines as well.

The valuation is based on a comparison of the valuation object with comparable objects (International Valuation Standards). As a property appraiser in the Czech Republic, I am often faced with the problem of how to quantify the degree of dissimilarity between an appraised and a comparable item. In the case of forming machine valuation, although we have comparable forming machines, there are almost always differences in essential characteristics, i.e., design, condition, and parameters between the forming machine being valued and the forming machines to be compared. Differences in design and condition should be assessed by the valuer based on his knowledge and experience.

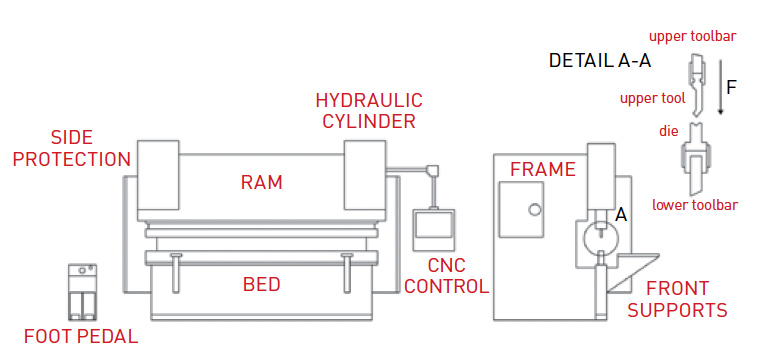

The aim of this paper is mainly to present the procedure of reduction of basic parameters to determining parameters. The determining parameters are those that determine the value of the forming machine. Forming machines are described by several parameters. However, there are no methods that can perform a multi-parameter price comparison with such a large number of parameters. Thus, the use of computational modelling is suggested. For the implementation of the derivation of the determining parameters, the forming machine of the bending press is selected.

The basic parts of the bending press are as follows:

The bending press is described by parameters that can be classified as follows:

i. Workspaces (p1 bending length, p2 throat, p3 table height,

p4 stroke, p5 distance between columns, and p6 daylight)

ii. Performance (p7 press force, p8 power)

iii. Efficiency (p9 speed of stoppers, p10 feed of the upper cross)

iv. Machine size (p11 length, p12 height, p13 width, p14 weight)

v. Other (p15 accuracy, p16 degree of automation)

A change in each of the above parameters from the groups of workspaces, performance, efficiency, machine size and others will affect the value of the press brake, but to varying degrees. To solve practical valuation problems, it therefore seems advisable that the comparison between the press brake being valued and the press brake used for comparison is primarily based on the examination of those parameters that have a determining influence on the price of the machine, i.e., they are price-determining.

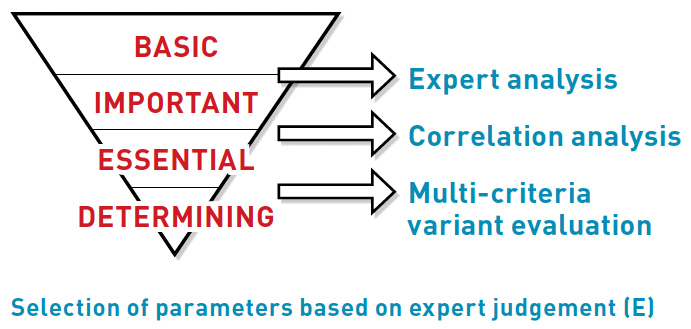

For this purpose, a method based on three-step parameter reduction is proposed. Expert analysis is used to select the important parameters from the group of essential parameters, correlation analysis is used to reduce the important parameters to essential parameters, and multi-criteria variant evaluation is used to select the determining parameters. This procedure is collectively referred to as the ECM method. This method describes a procedure for controlled parameter reduction with minimal loss of essential information. The ECM method has been published 1,2,3.

The scheme of the ECM method is as follows:

Selection of parameters based on expert judgement (E)

Press brakes are designed to meet the high demands and requirements of users. In terms of assessing the utility of a press brake, the most important factor is the variety of products that can be produced on the machine. The variety of the product is determined by the size of the material to be processed and the operation that the machine can perform.

To reduce the basic parameters, it is necessary to express, in the form of questions, the possibilities of the forming machine. I propose to formulate questions for the bending press in relation to the utility:

- WHAT IS THE PRODUCT MADE OF? In a fencing operation, it is usually sheets of different shapes, dimensions and thicknesses.

- HOW IS THE PRODUCT MADE? By bending the sheet metal to different degrees with a tool in a die.

| QUESTION/INFLUENCE | bending press |

| What is the product made of? | Sheets of different shapes, sizes, and thicknesses. |

| Influence of parameters | Group workspace and performance. |

| HOW is the product made? | By bending. |

| Influence of parameters | – |

The utility depends on the parameters from the working space group, i.e., on the parameters p1 bending length, p2 throat, p3 table height, p4 stroke, p5 distance between columns and p6 daylight, as well as on the parameters describing the performance characteristics of the machine, i.e., on the parameters p7 press force and p8 power. Parameter p3 table height from the workspace group, is primarily an ergonomic parameter and does not affect the utility. The other parameters listed in the other groups will not be very significant in terms of the variety of products produced on the bending press.

Parameter selection by excluding linearly dependent parameters (C)

This step is performed in the ECM method in order not to duplicate the mutually linearly dependent parameters in the computational model. To quantify the tightness of the parameter relationships, the Pearson correlation coefficient is used in this paper. For the purpose of parameter reduction by the ECM method, only parameters with a tightness of correlation very strong in the range of ‹0.80; 1.00›. Data from common information sources are used to verify the linear interdependence of important parameters (found for parameters from the same groups). The exclusion of linearly dependent parameters (correlation matrix created, (e.g., in Excel or Gretl) allows reducing the seven important parameters to four. These are the parameters from the working space group p1 bending length, p2 throat and p4 stroke, and the parameter from the performance group p7 press force.

Parameter selection by multi-criteria variant evaluation (M)

I propose to use the multi-criteria variant evaluation method to find the determining parameters. The aim of the analysis is to find out which of the essential parameters p1 bending length, p2 throat, p4 stroke and p7 press force are the determining (pricing) parameters for the comparison of forming machines. In this case, the variants are the individual essential parameters which are further assessed according to the evaluation criteria introduced below.

From the point of view of the machine manufacturer, the cost of production is always important. Simplistically, these costs can be divided into the costs incurred for the actual production (costs incurred directly by the manufacturer), the costs incurred for the supplies from the subcontractor (purchase of components), and the costs for the assembly of the forming machine.

Given the problem under consideration, the use of a nominal (binary) scale seems to be the best option. The nominal scale method of evaluating variants is based on the application of agreement or disagreement, which is defined by a binary logical value of 1 (agreement) and 0 (disagreement). The variants evaluated are unbiased with respect to the criterion being evaluated. This method does not consider the preferences of each criterion, and the weights of each criterion are not considered. The ranking of the variants is determined based on the simple sum of the values given in the criterion matrix. The certainty of each parameter will be assessed and evaluated according to its impact on the selected criteria: cost of own production, cost of subcontractor, and cost of installation. The evaluation of the criterion matrix shows that, in terms of the total cost of production of the press brake, the parameters p1 bending length (3 preferred) and p7 press force (3 preferred) can be considered as the determining parameters of the machine.

Evaluation of criterion matrix:

| Essential parameters | Criterion- cost of own production | Criterion- cost of subcontractors | Criterion- installation costs | Result |

| p1 bending length | 1 | 1 | 1 | 3 |

| p2 throat | 0 | 1 | 0 | 1 |

| p4 stroke | 0 | 0 | 0 | 0 |

| p7 press force | 1 | 1 | 1 | 3 |

Conditions are set for evaluation purposes:

- a preference count of 0 and 1 means that the parameter is not a determinant, and

- the number of preferences 2 and 3 means that the parameter is determinant.

Computational modelling

For the practical use of the ECM method, it is necessary to build a computational model. The data on the basic prices of a hydraulically driven press brake with different values of the determining parameters p1 bending length and p7 pressing force were obtained through the usual information sources. The regression statistics is created in Gretl (more detailed derivation is stored by the author of the paper). The ordinary least squares (OLS) method is used to obtain estimates of the LRM parameters. The p-values of the regression coefficients for the parameters p1 bending length and p7 pressing force and the absolute component are smaller than the chosen significance level a=0,05, i.e., the analysed parameters are statistically significant at the chosen significance level a=0,05. The adjusted coefficient of determination R2adj = 0.990563 explains what percentage of the variability in the dependent variable can be explained by the chosen LRM (the model can explain 99.06 % of the variability in the variable). The significance of the model is captured by the P-value (F) = 3.55e-07, which is less than the chosen significance level a=0,05. The LRM is statistically significant and is considered appropriate to capture the variability of the dependent variable.

The estimated LRM takes the form: y=51469.33+38.09p7+13.84p1

where y is the selling price/value of the bending press and the values 51469.33 and 38.09 and 13.84 are the estimated regression coefficients β0, β1 and β2 respectively.

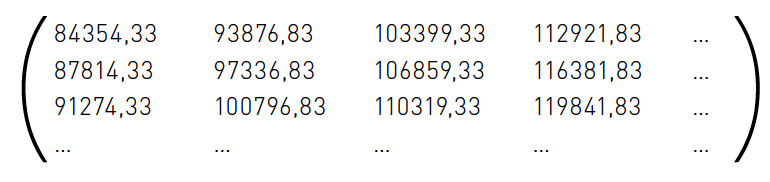

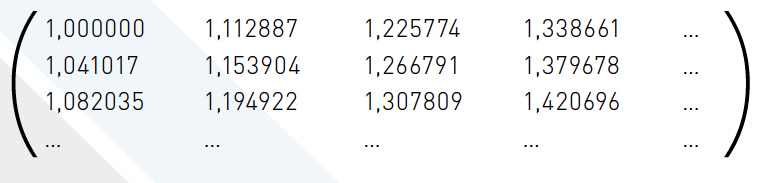

For practical use of the estimated LRM of a bending press, it is necessary to express the established dependence of the price of the bending press on the determining parameters by means of proportional numbers so that the current price level of bending presses can be considered in the normal valuation, regardless of the price level used to create the estimated LRM. The general matrix of values, after inserting the values of the parameters p7 press force and p1 bending length into the estimated LRM, takes the form:

The dependent variable for the estimated LRM is the price of the press brake in €. For faster use of computational modelling, a conversion is performed. The current trend is to maximize the automation of the valuation process and make it faster. The conversion converts the values in € in the general matrix into dimensionless values and thus allows to import the value of the bending press in different currencies, e.g., in £, €, $.

The normalized matrix of values has the form:

The ordinary least squares (OLS) method yields estimate of the parameters of the normalized LRM of the form:

cn=0.610156+0.000451p7+0.000164p1

where cn is the normalized selling price/value of the bending press and the values 0.610156, 0.000451 and 0.000164 are the estimated regression coefficients β0, β1 and β2 respectively. After fitting the specific values of parameters p7 and p1 to the normalized LRM, we obtain the normalized coefficient of CN [-].

In a practical valuation, it is necessary to compare the valued bending press with a comparable bending press. The difference (dissimilarity) is expressed by the ratio of the standardised CN coefficients of the valuation press and the comparable press:

COP=CNO/CNS

where CNO is the normalized coefficient of the valued forming machine [-] and CNS is the normalized coefficient of the comparable forming machine [-].

Verification of results

Verification of the functionality of the standardized LRM in valuation practice is performed on samples of four hydraulically driven bending presses from different manufacturers, namely LVD, TRUMPF and DURMA.

| Manufacturer/label | PPEC 220/42 | AD-SERVO 40175 | TruBend 5050 | AD-R 30135 |

| p7 press force | 2200 kN | 1750 kN | 500 kN | 1350 kN |

| p1 bending length | 4270 mm | 4050 mm | 1275 mm | 3050 mm |

Comparable bending presses:

| Manufacturer/label | PPEC 170/42 | AD-SERVO 30135 | TruBend 5230 | AD-R 40175 |

| p7 press force | 1700 kN | 1350 kN | 2300 kN | 1750 kN |

| p1 bending length | 4270 mm | 3050 mm | 3230 mm | 4050 mm |

| Values of determining parameters: | Lower than the valued | Higher than the valued | ||

| Selling price/value | 95000 € | 66617 € | 186000 € | 47187 € |

Comparison of normalized coefficients and estimates of bending press values:

| Manufacturer | LVD | DURMA | TRUMPF | DURMA |

| CNO | 2.304 | 2.065 | 1.045 | 1.720 |

| CNS | 2.078 | 1.720 | 2.179 | 2.065 |

| COP=CNO/CNS | 1.109 | 1.200 | 0.480 | 0.833 |

| Estimate=selling price/value ·COP | 105320 € | 79966 € | 89225 € | 39310 € |

Estimation deviations:

| Manufacturer/label | PPEC 220/42 | AD-SERVO 40175 | TruBend 5050 | AD-R 30135 |

| Estimate | 105320 € | 79966 € | 89225 € | 39310 € |

| Real value | 100000 € | 77720 € | 87000 € | 37010 € |

| Deviation | 5.3 % | 2.9 % | 2.6 % | 6.2 % |

Conclusion

The derivation of the coefficient of difference COP, which considers the differences in the determining parameters, is essential for the comparison of forming machines. LRM and computational modelling were used in the research to derive the COP coefficient. The proposed procedure was tested on a press brake forming machine (in the next phase of the research, testing is performed on other stands). The determining parameters found by the ECM method were used to create the estimated or optimized LRM of the forming machines. In cases where COP=1, it is 100% comparability in the determining parameters. The differences between the value calculated using the proposed model and the sale price/value

do not exceed 7%. The new approach presented in this paper, i.e., both the ECM method and the application of the COP dissimilarity coefficient, which considers differences in the determining parameters, can be advantageously used to quantify differences in advertised prices found in the market.

End notes

- ŠŮSTEK, Roman. Use of Multicriterion Method in Significance Analysis. Odhadce a oceňování majetku. 2021, Vol. 27, No. 1-2, pp. 20−26.

- 2) ŠŮSTEK, Roman. Metoda ECM a její aplikace při oceňování tvářecích strojů. Young Science. 2022, Vol. 10, No. 6, pp. 48−60.

3) ŠŮSTEK, Roman. Selection of Determining Parameters Using the ECM Model. Scientific supplement of ANNALS of FACULTY ENGINEERING HUNEDOARA – INTERNATIONAL JOURNAL of ENGINEERING. 2022, Vol. 20, No. 3, pp. 155−158.